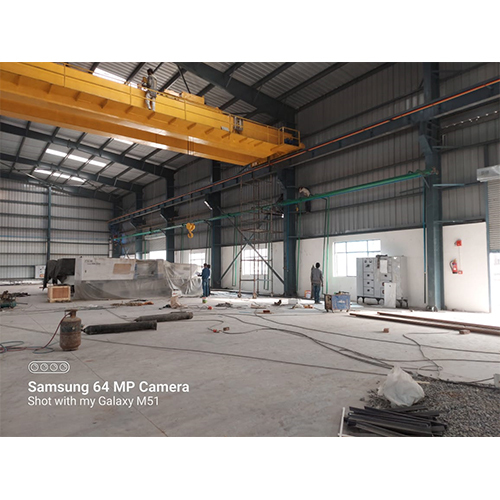

Single Girder EOT Crane

Product Details:

- Product Type Single Girder EOT Crane

- Usage industrial

- Condition New

- Material Mild Steel

200000.00 - 1000000.00 INR/Unit

X

Single Girder EOT Crane Price And Quantity

- 1 Unit

- 200000.00 - 1000000.00 INR/Unit

Single Girder EOT Crane Product Specifications

- Mild Steel

- industrial

- New

- Single Girder EOT Crane

Single Girder EOT Crane Trade Information

- 100 Unit Per Week

- 7 Days

Product Description

Enter Buying Requirement Details

Other Products in 'EOT Crane' category

"We are dealing only in North India".